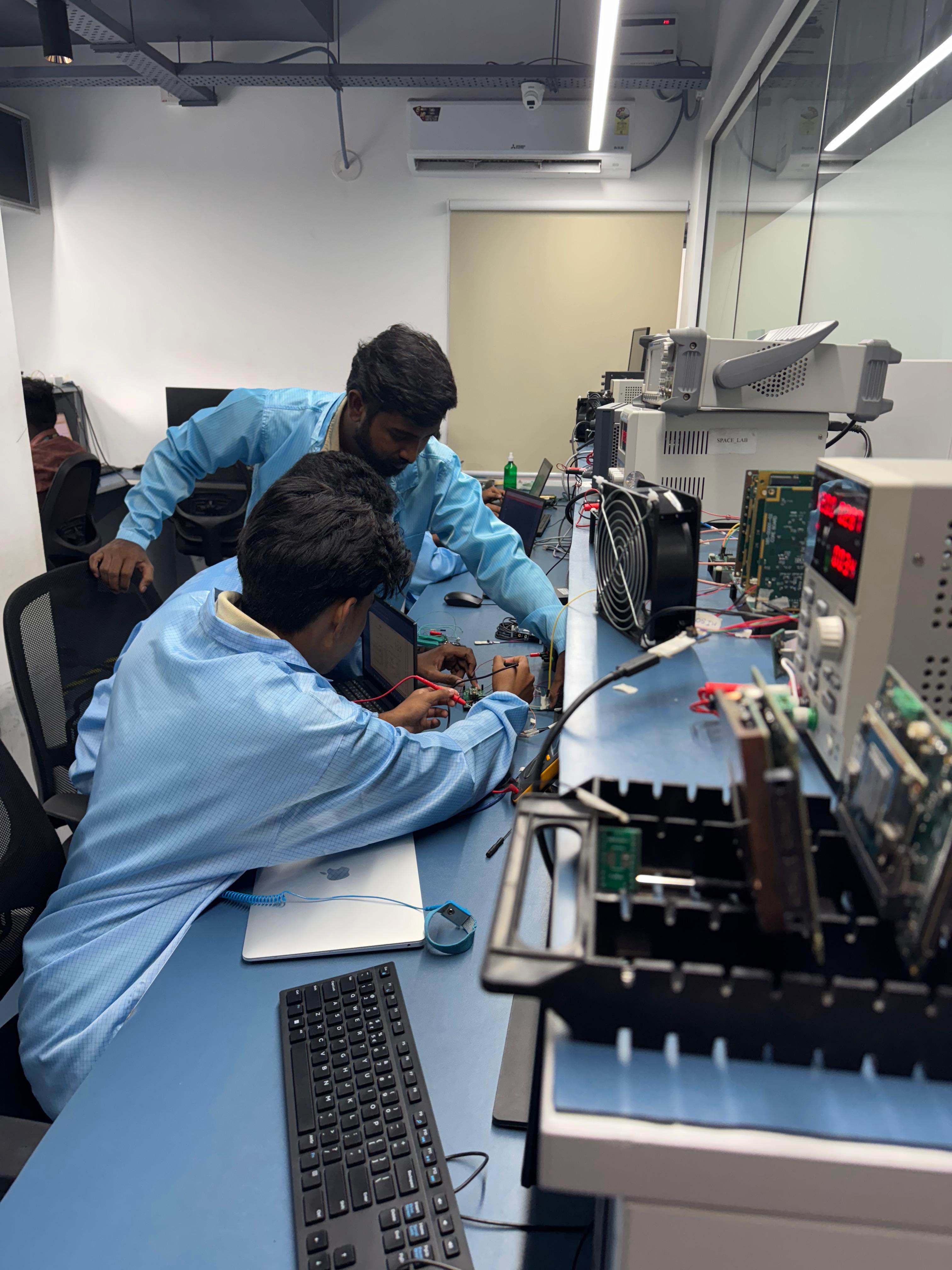

I came into the internship with a lot to be learned when it came to the software concepts I would need to apply when writing the communication software as well as the software to run and read back the different components properly.

I was provided with useful resources to learn everything I needed to move forward and the mentors were there to help every step of the way.

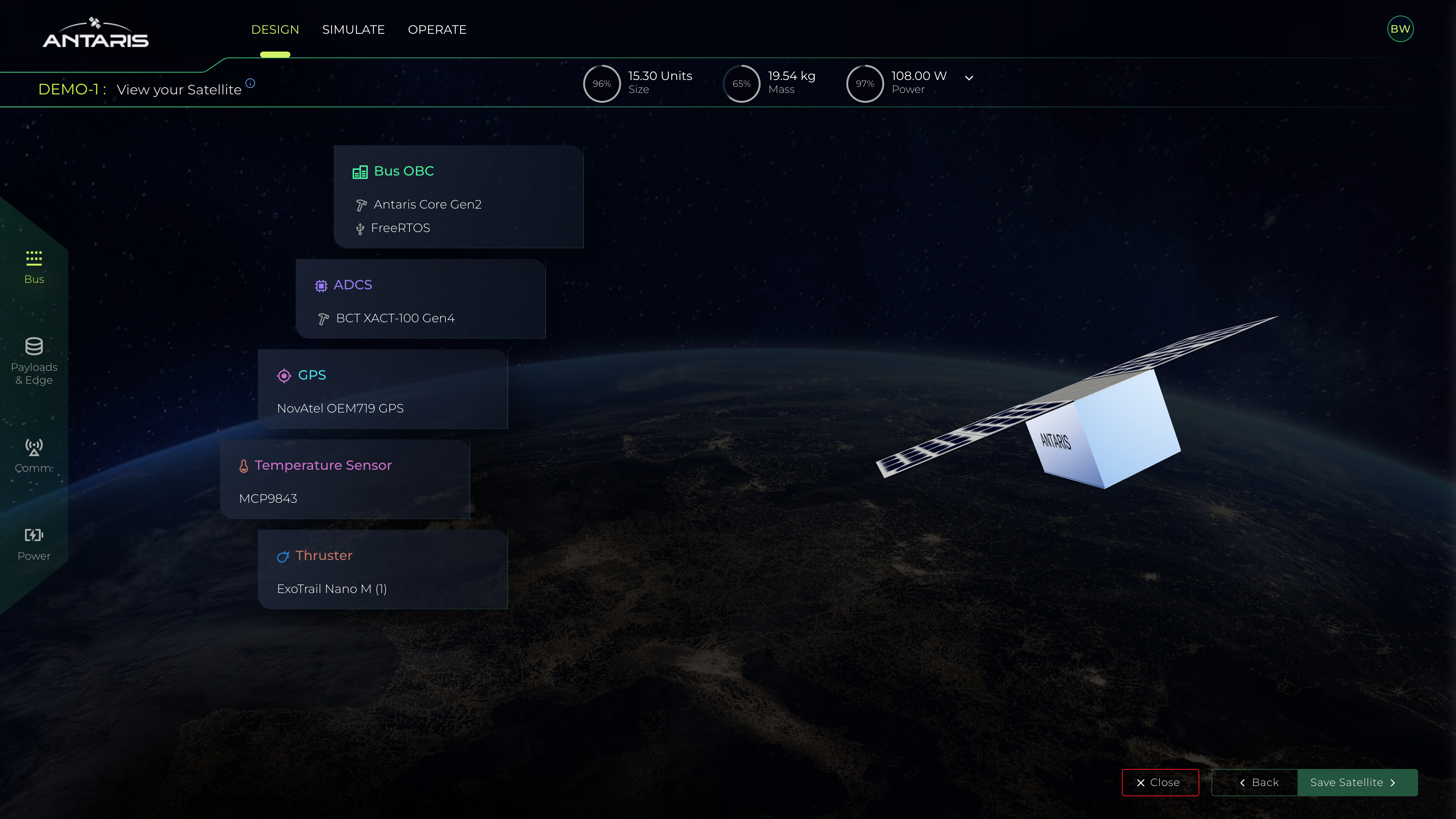

I began by implementing communication between the ground station, obc, and the payload computer. I needed to create a protocol to ensure that all components were encoding and decoding the correct data. This involved 3 separate threads and 2 queues as well as each respective function to efficiently receive, decode, encode, and relay data to the next target.

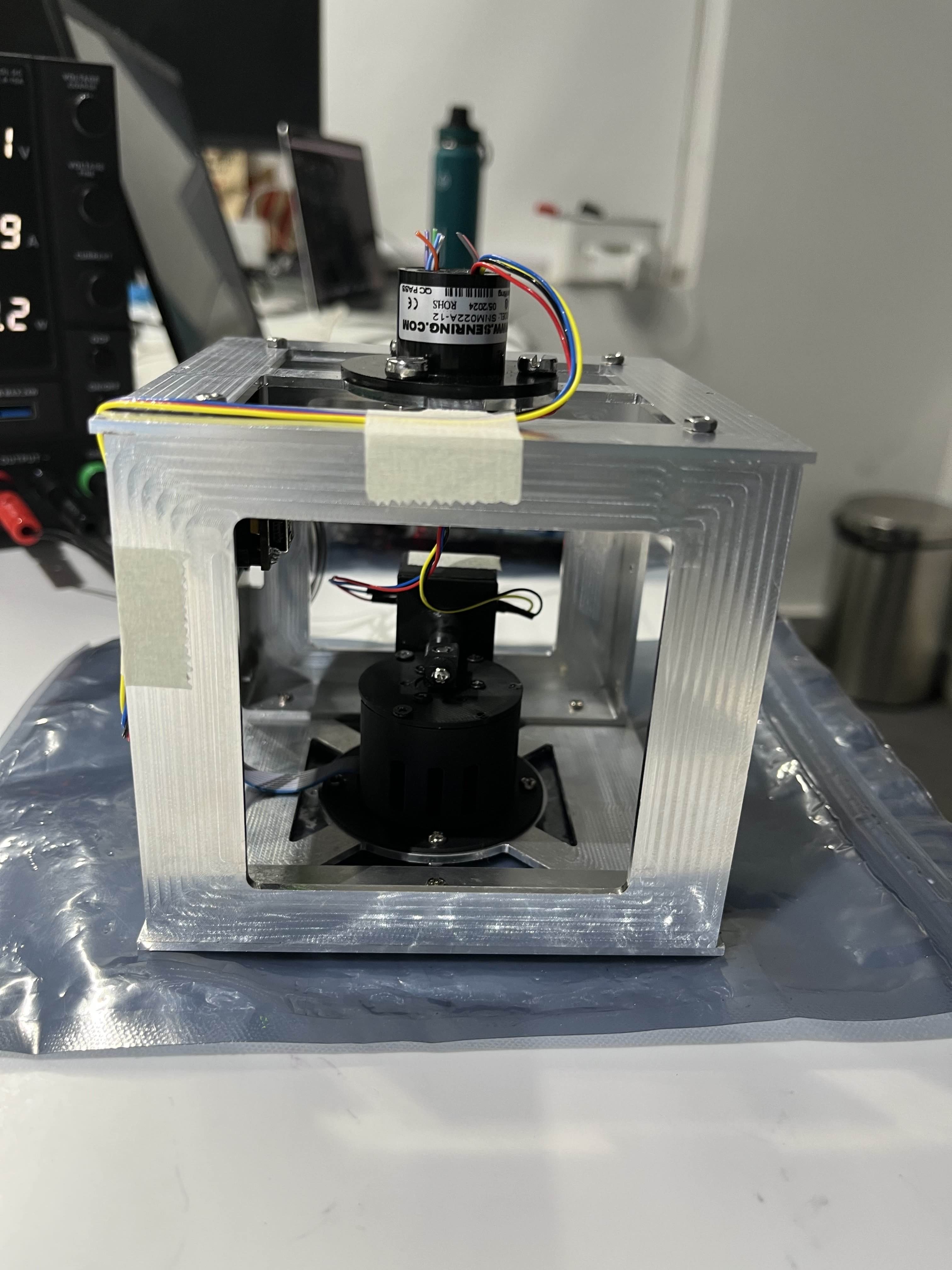

Next, I turned my focus to writing the software and testing all of the components that would be used, including the bringup of the carrier board, and testing of the motor and force sensor. This was the step which came with the most issues to resolve, but with help from the mentors we got everything to work.

Then, I went through multiple iterations of the hardware design due to persistent issues, though finally I was able to get it to work as intended.

After I finalized and assembled the hardware design we performed full integrated testing with all of the parts mounted, with routing commands from the ground station through the pipeline.